For temperature-controlled manufacturing, renewable energy can be a game changer. At Suncream Dairies, they’ve embedded solar power into the operations at their Tamworth site to transform their carbon footprint.

Suncream Dairies have been producing ice cream since 1934; providing wholesale ice cream to their client base with a range of flavours, dietary options, and packaging produced on-site. As their operations continue to grow, the team at Suncream Dairies wanted to tackle both their carbon footprint and their cost base.

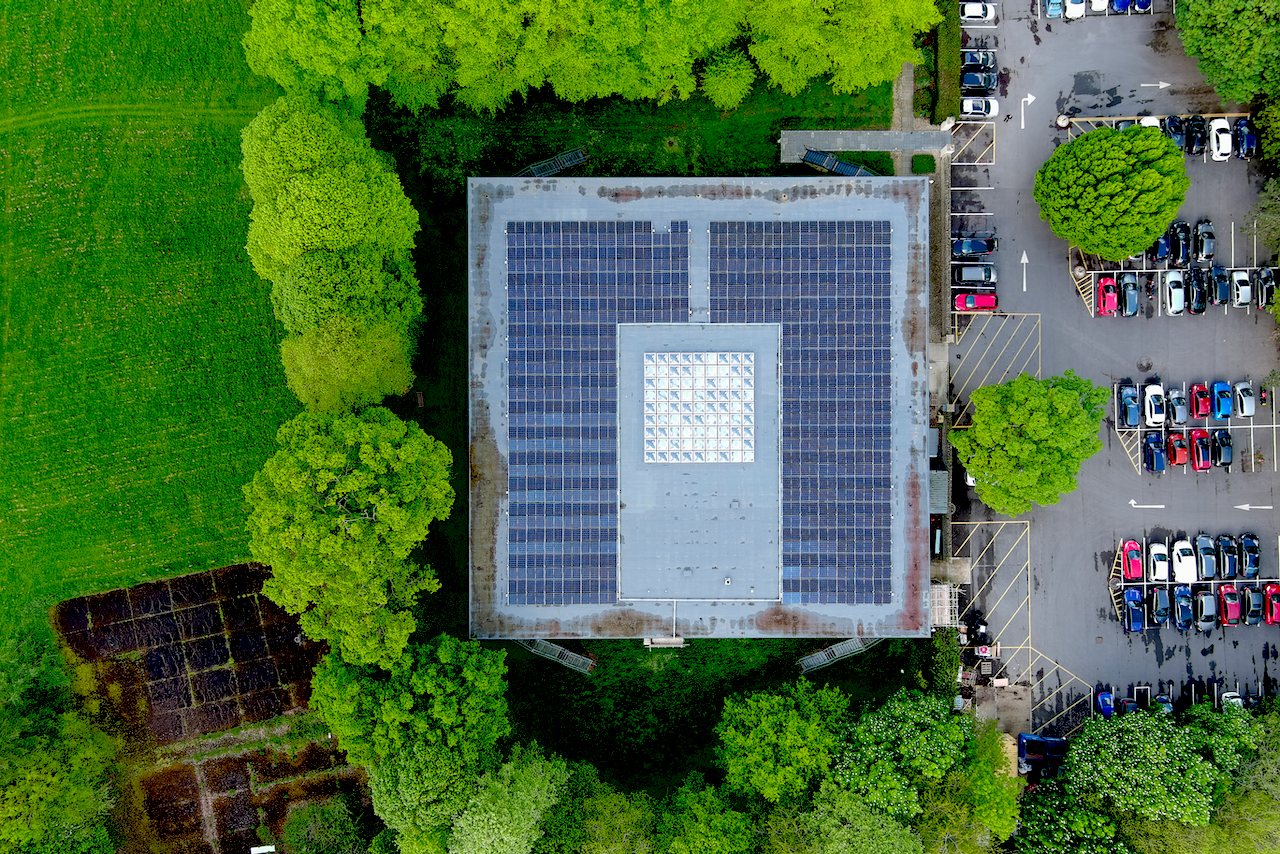

Our in-house team have installed around 400 modules onto their rooftop, generating roughly 193,000kWh of clean electricity a year. With a payback period of just under 4 years, this system is going to save Suncream Dairies an estimated £37,611 a year, savings that will grow to £890,000 over the next 25 years. For any business, these energy costs savings are welcome, but for ice cream producers like Suncream Dairies they can have an especially massive impact.

Ice cream production and storage necessitate a higher degree of energy usage to maintain appropriate temperatures at each stage of the process. That high energy usage leaves the industry subject to both volatile energy prices and the growing impact of climate change. For Suncream Dairies, their new solar installation will make this energy consumption more manageable from a cost and carbon perspective; reducing their carbon footprint by 44 annual tonnes of CO2e, which will increase to roughly 1,065 tonnes across the systems lifetime.

Learn more about our projects for other temperature controlled businesses like Rodda’s here.