Update(s): January & April 2023

The Interfish system performed so well over its first two years of operation that the client asked us to extend the system with an additional 300 kW – and then again with another 150 kW – bringing the total to just under one megawatt.

Further extensions and developments of the system are still under consideration.

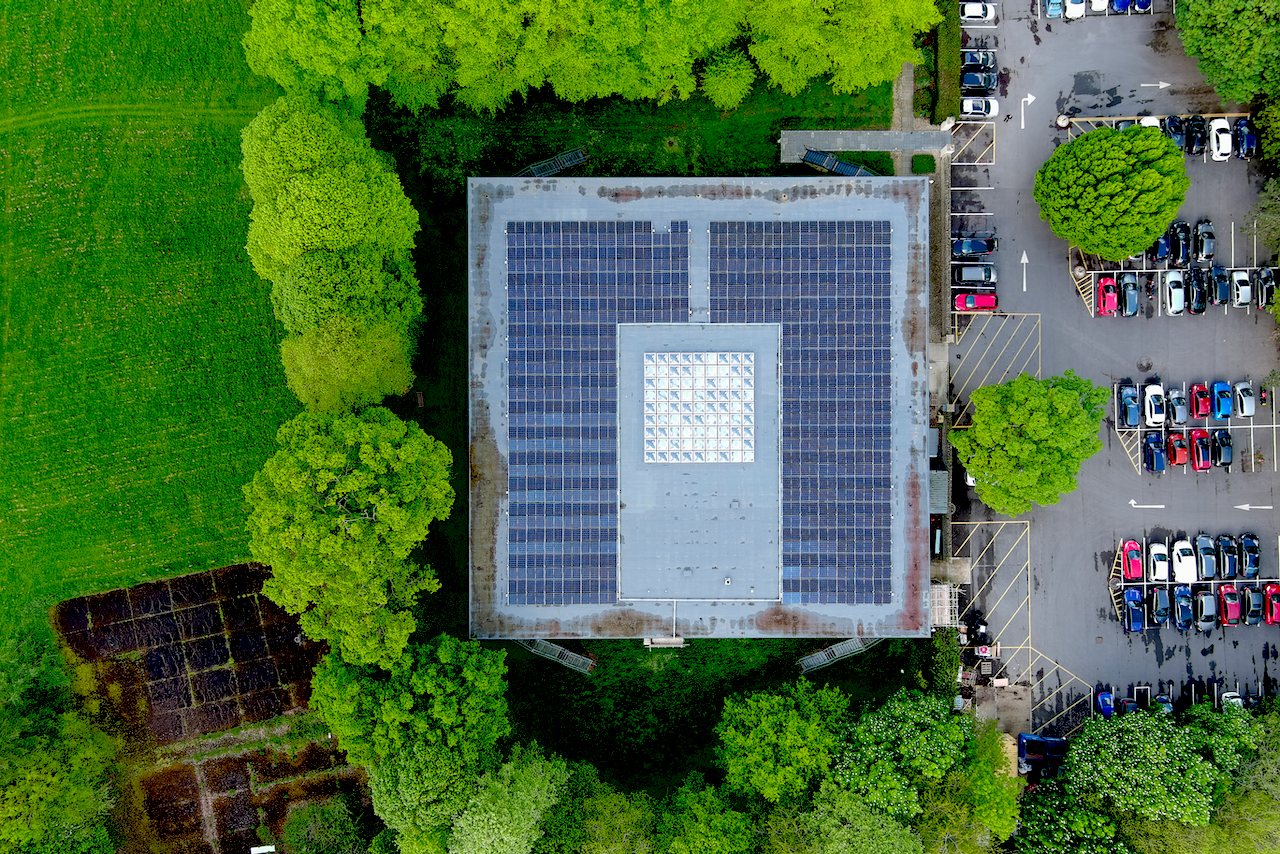

With massive cold storage capacity in their 5,000 sq m facility, this food manufacturer’s high baseload demand is being met in part by power from a 1,300 panel, 508 kW system – our largest roof-mount to date.

This will generate electricity at an equivalent forward cost of just 4p per kWh, and provide nearly 500 MWh per year, with close to 100% being consumed on-site. It will also save well over three thousand tonnes of CO2 emissions during its 25 year operational life span.

The installation took place between November and January during one of the wettest and windiest winters on record. Despite the site’s waterfront location giving full exposure to the weather – and the added challenge of a major re-roofing project being run at the same time – all panels and rails were installed on schedule.

With multiple roof pitches, orientations and vents to contend with, this was a complex design. And at 15 metres high, safety was a major focus for both the installation and subsequent maintenance.

Using SolarEdge inverters and optimisers helped with the design challenges (as well as offering superior panel-level monitoring) and the safety aspect was addressed by incorporating an access walkway with fall-protection lifeline from STQ Vantage.