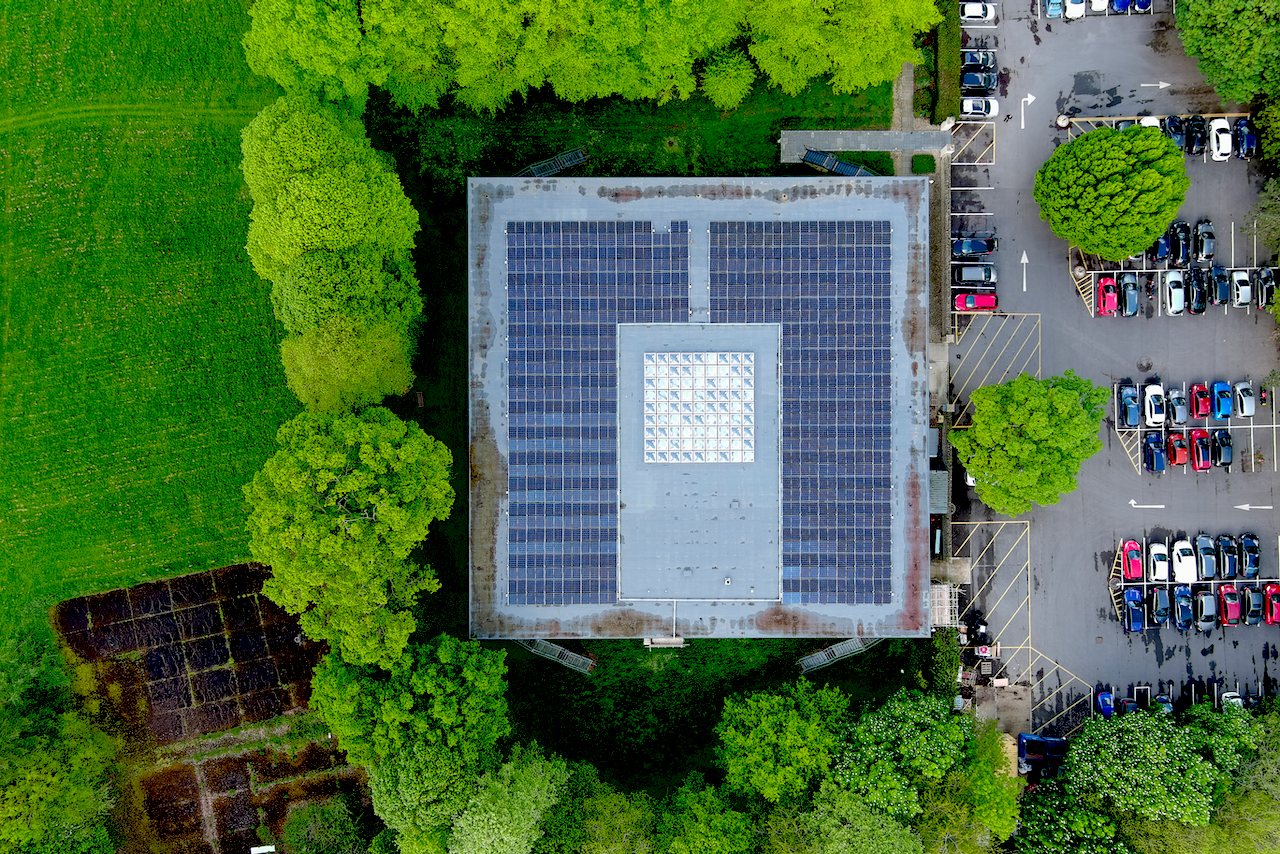

Hillbrush are the UK’s largest manufacturer of high-quality brush ware and hygienic cleaning tools. In 2017, they started their move into renewable energy with their first CleanEarth installation: a 245 kWp system on a new purpose-built manufacturing and office building at Norwood Park.

UPDATED December 2025

The installation formed a key element of Hillbrush’s environmental policy, which also includes sensor-controlled LED lighting, energy-efficient moulding machinery, and electric car charging points. Not only had Hillbrush taken steps for their sustainability goals, but they shielded themselves from volatile energy prices – with a solar PV system designed for almost all their self-generated electricity to be consumed on-site.

Being a busy manufacturing site, it was important that the project was managed without disruption to the day-to-day operations. CleanEarth completed the installation within two weeks with minimal impact on the business. After such a successful installation process, the system would exceed generation forecasts by 10% in its first two years. It would then receive its first expansion of 200 kWp in 2021. With this additional generation, nearly half of Hillbrush’s electricity demand was met by their solar PV system.

Following this second successful installation, they commissioned a third CleanEarth solar PV addition for their warehouse in 2023, adding a further 264 kWp. Then in 2025, they added a fourth phase of solar, with an 82kWp system extension that brings their total annual generation to close to 752,000 kWh.

Hillbrush’s carbon savings come to 223 tonnes each year, which will add up to 4,750 tonnes of CO2 reductions within the system’s combined lifetimes. In that same time, Hillbrush will have saved over two million pounds in energy costs.

As of 2024, Hillbrush are Climate Partner certified and have an FSC certification, using both sustainably sourced wood and recycled plastic for their products. They’re working on obtaining 14001 and B-Corp certifications with a view to extend to scope 3 carbon accounting.

Each CleanEarth installation takes Hillbrush’s sustainability goals another step further and supports their growth with every kWh.