The landscape inland of St Austell in Cornwall bears the indelible mark of nearly 300 years of mining activity.

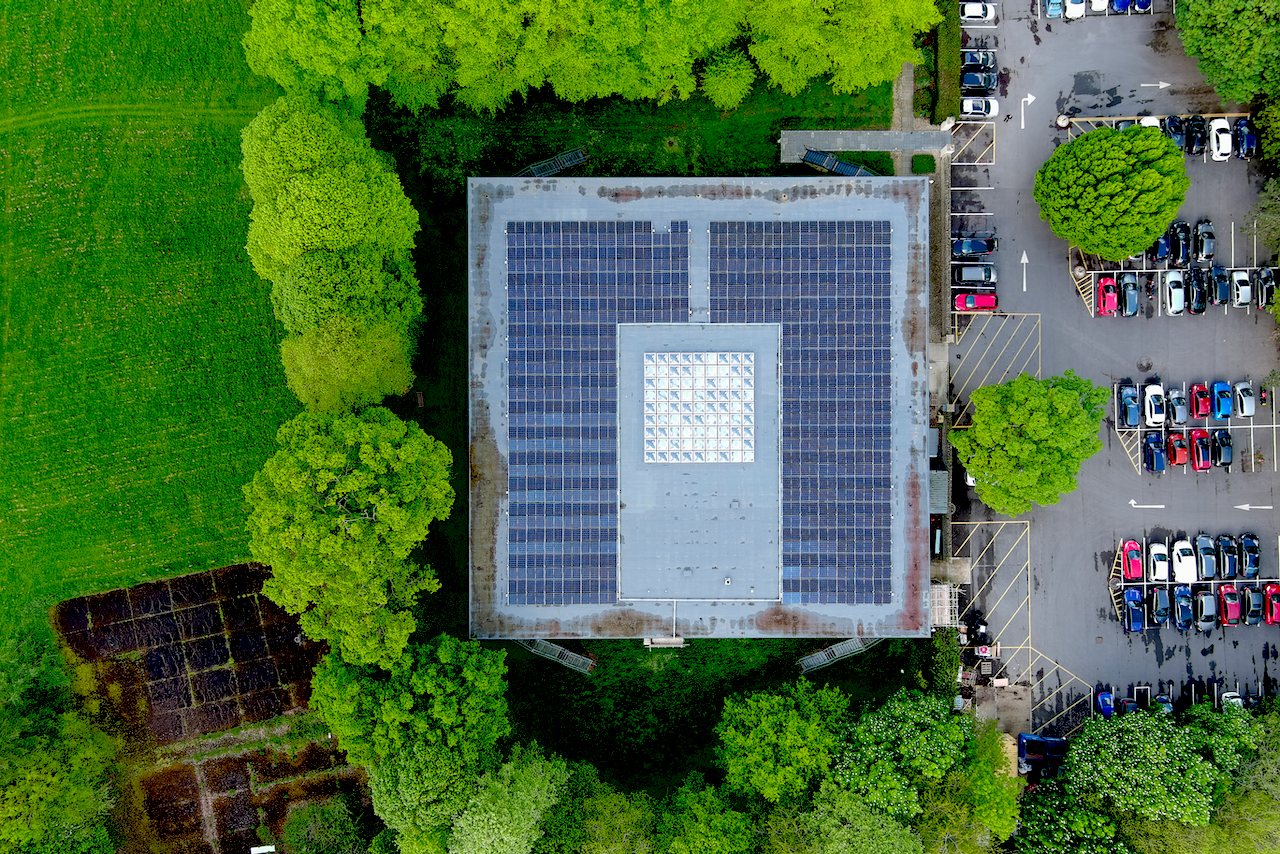

Home to the largest china clay deposits in the world, this dramatic terrain is dominated by the hills created out of some 600 million tonnes of spoil material. Our 2.5 MW solar farm is located on one of the area’s largest mica dams, and the six acre site’s industrial provenance presented some interesting geotechnical challenges.

Flood prevention, subsidence risk, topsoil protection

The Lower Ninestones project called for protection against a 1 in 100 year flooding event, and included extensive work on drainage as well as the raising of all equipment half a metre above ground level to keep it clear of any flood waters.

Piling into the spoil material took particular care, with a higher number of test piles being deployed and a three week wait before checking for settlement.

The risk of subsidence is greater if dusty topsoil is being constantly eroded by water and weathering, so the site was hydro-seeded to promote the growth of vegetation to hold the topsoil together.

Although the Lower Ninestones site is not currently operational, there is still active china clay quarrying in the area, so the project needed to adhere to the regulations for health and safety at quarries. This meant extra protection for all cabling, with high voltage runs in steel wire armoured cable and the low voltage DC cabling in protective ducting.

Several miles of trenches were dug, including a 2.5 km stretch from the inverter station to the 33 kV grid connection – the longest (so far) for any CleanEarth solar PV installation.