UPDATE: December 2021

On the back of four years of generation – and associated savings in energy costs and carbon emissions – Hillbrush commissioned CleanEarth to extend their solar PV system.

The additional 200 kW brings their total generating capacity to 445 kW, providing close to half of Hillbrush’s electricity demand and saving 150 tonnes of CO2 emissions every year.

UPDATE: November 2019

In the two years since commissioning in late 2017, the Hillbrush system has consistently exceeded its generation forecasts by some 10%.

It has generated nearly 600,000 kWh, saving over 200 tonnes of CO2 emissions and providing nearly 25% of Hillbrush’s total electricity demand.

Since the installation, as further evidence of their commitment to decarbonisation, Hillbrush have installed EV chargers and signed up to the Planet Mark sustainability certification.

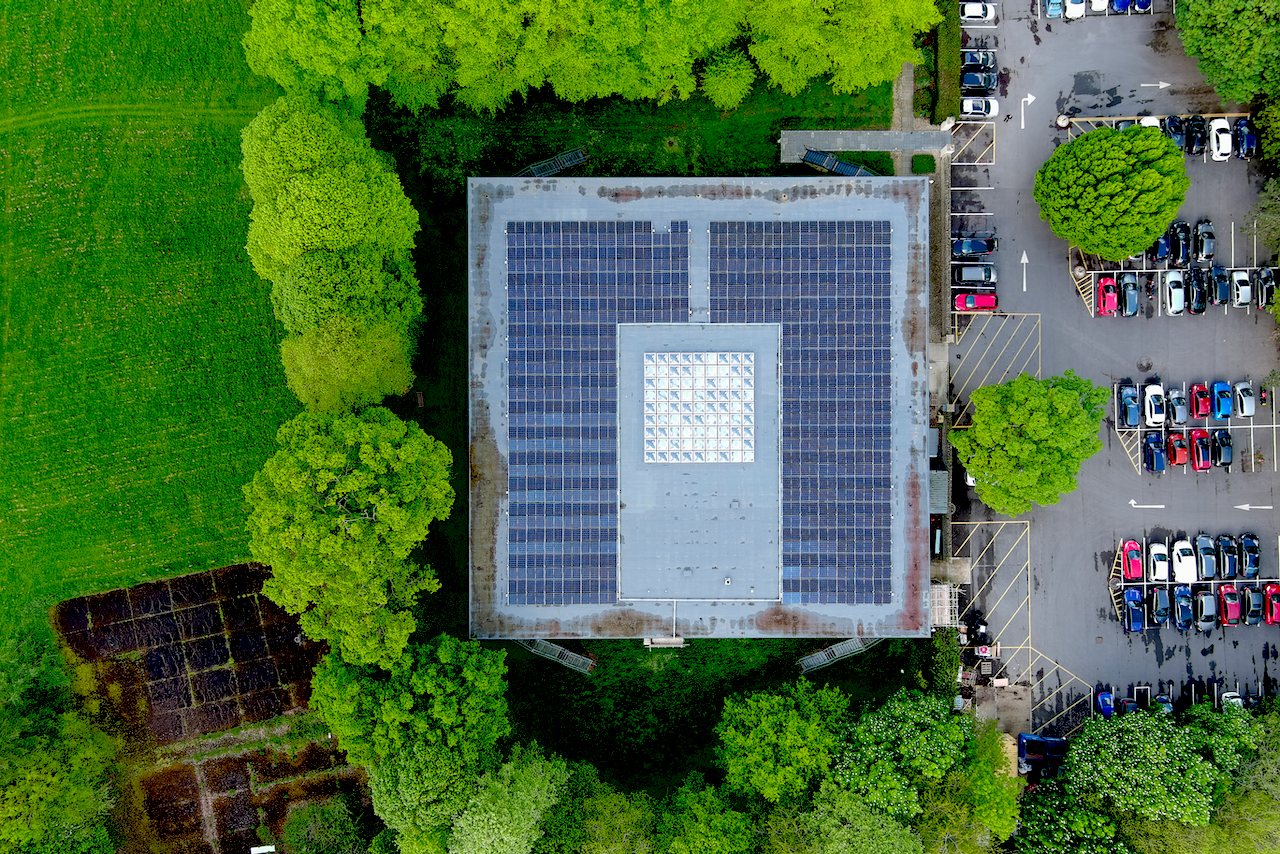

Hillbrush are the UK’s largest manufacturer of high-quality brush ware and hygienic cleaning tools. They recently opened a purpose built manufacturing and office building at Norwood Park which clearly demonstrates their environmental credentials.

The 245 kWp, solar array will generate around 230,000kWh of electricity a year to use directly on site. The installation is a key element of Hillbrush’s environmental policy which also includes sensor controlled LED lighting, energy-efficient moulding machinery, and electric car charging points.

As well as meeting the company’s sustainability goals, the solar PV system will also help protect Hillbrush against volatile energy prices. The system was designed so that almost all of the self-generated electricity is consumed on-site. As CleanEarth’s Operations Director, Tristan Grimes, explains: “this means they can fix a substantial part of their electricity costs for the next 25 years, helping them remain competitive in the global market.”

Being a busy manufacturing site, it was important that the project was managed without disruption to the day-to-day operations, CleanEarth completed the installation within two weeks with minimal impact on the business.